Australian Standards for Structural Steel Coatings: Painting & Galvanizing Best Practices

Structural steel frameworks are constantly exposed to moisture, salts and pollutants that can trigger rapid corrosion. In Australia’s diverse climates, stringent Australian Standards guide how to apply protective coatings for long-term steel protection. For example, AS/NZS 2312 provides comprehensive guidelines on specifying paint coating systems for structural steel, and AS/NZS 4680 defines hot‑dip galvanizing requirements. These standards help architects, engineers and contractors choose the right protective schemes for each environment (Implementing the AS-NZS 2312 Coating Standard Update) (specManual_08_Final_01.indd). In practice, designers use AS/NZS 2312 (Paint Coatings) and AS/NZS 4680 (Galvanizing) – along with AS/NZS 2312.2 (Hot-Dip Galvanizing design) – to ensure steel elements meet both aesthetic and durability goals. Partnering with a knowledgeable supplier like Staren Vietnam ensures your project’s steel coatings are compliant with these Australian Standards from the start.

Painting Structural Steel – AS/NZS 2312 Guidelines

Protective painting is the most common coating method for structural steel. AS/NZS 2312 (especially Part 1: Paint Coatings) lays out how to select and apply multi‐layer paint systems according to the structure’s corrosion exposure. This includes advice on surface preparation (e.g. abrasive blast cleaning), primer and intermediate coats, and weather‑resistant topcoats matched to corrosivity categories (C1 through C5, defined in AS 4312) (Advisory Note 39) (Australian/New Zealand Standard | PDF | Corrosion | Paint). For instance, a bridge in an urban environment (C3) might use a zinc‐rich primer, epoxy midcoat and polyurethane finish. AS/NZS 2312 explicitly states its aim “to provide guidance for architects, engineers, builders… on paint coating systems for the protection of steel work against corrosion”. In other words, the standard lets designers choose coating systems “based on expected service life” for different environments. High-performance paint systems under AS/NZS 2312 can be expected to last many years before the first maintenance coat; exact lifespans depend on factors like climate and maintenance regime. By following AS/NZS 2312’s recommended paint schemes (and local experience), constructors can balance appearance and cost against durability.

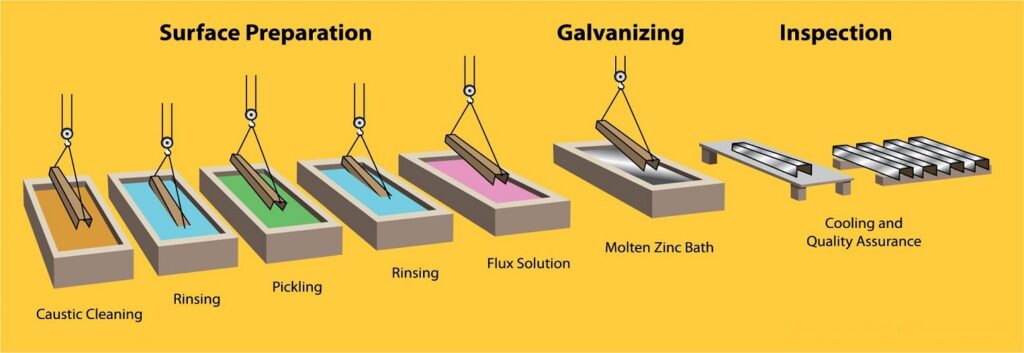

Galvanizing Structural Steel – AS/NZS 4680 & AS/NZS 2312.2 Guidelines

Hot‑dip galvanizing is an alternative that metallurgically bonds a thick zinc layer to steel, offering inherently long corrosion protection. AS/NZS 4680:2006 is the key standard for galvanizing in Australia – it’s even called “the defining standard for hot‑dip galvanized (zinc) coatings” here (specManual_08_Final_01.indd). This standard specifies the minimum zinc coating mass (or thickness) required on different steel sections. For example, AS/NZS 4680 “specifies minimum coating thickness requirements for steel of various section thicknesses”, including both local (spot) thickness and overall average thickness values. In practice, this means a 6 mm steel beam might be galvanized to at least ~85 μm locally (≈600 g/m² of zinc).

Designers also use AS/NZS 2312 Part 2 (Hot Dip Galvanizing) for life‐cycle planning. This part aligns with international corrosivity data so engineers can predict service life. In fact, AS/NZS 2312.2 “references the latest international corrosivity and design Standards for HDG,” meaning the zinc coating’s “life to first maintenance” matches observed long-term performance (Advisory Note 39). For example, with an 85 μm zinc coating, AS/NZS 2312.2 projects protection from rust for over 50 years in a C3 (moderate) environment. In harsher coastal or industrial zones (C4/C5), thicker coatings or duplex systems are recommended to extend life.

In summary, properly galvanized steel – applied per AS/NZS 4680 and designed per AS/NZS 2312.2 – can endure decades of exposure with minimal maintenance. While initial galvanizing cost is higher than a single paint coat, the long service life often yields lower total lifecycle cost. Importantly, both AS/NZS 2312 and AS/NZS 4680 emphasize that steel design and coating choice must consider atmospheric categories (per ISO 9223/AS 4312) (Advisory Note 39). Using the right coating thickness or system for your corrosivity category is key to steel protection.

Comparing Coating Strategies: Paint vs Galvanize (and Duplex)

Choosing between paint and galvanize (or both) depends on project requirements. The standards provide guidance for all methods:

- Painted Coatings: AS/NZS 2312.1 details multi‐coat paint systems (surface prep, primers, midcoats, topcoats) tailored by environment. Paint allows color choices and is cost-effective for moderate exposures. However, painted steel will need periodic repainting (maintenance recoats) as instructed by the standard.

- Galvanized Coatings: AS/NZS 4680 governs zinc thickness; galvanizing offers a thick inorganic barrier. In practice, coatings designed via AS/NZS 2312.2 can last 50+ years in mild environments (Advisory Note 39) (specManual_08_Final_01.indd). Galvanized steel resists damage well, but requires proper design (vent holes, tolerances) for complex shapes.

- Duplex Systems: Painting over galvanized steel combines benefits. AS/NZS 2312.2 even includes guidance on duplex systems. Studies show that a duplex coating can increase service life well beyond either method alone – often 1.5–2.3× longer. In corrosive settings (marine, industrial), a zinc primer plus robust paint topcoat provides maximum durability.

In all cases, the standards ensure coating specifications (thickness, type, quality) match the site’s corrosivity category. Whether using paint or galvanize, AS/NZS 2312 directs designers to targets like dry film thickness and maintenance intervals, while AS/NZS 4680 secures zinc coating quality. This standardized approach lets contractors and engineers compare the total cost of each strategy over the structure’s life.

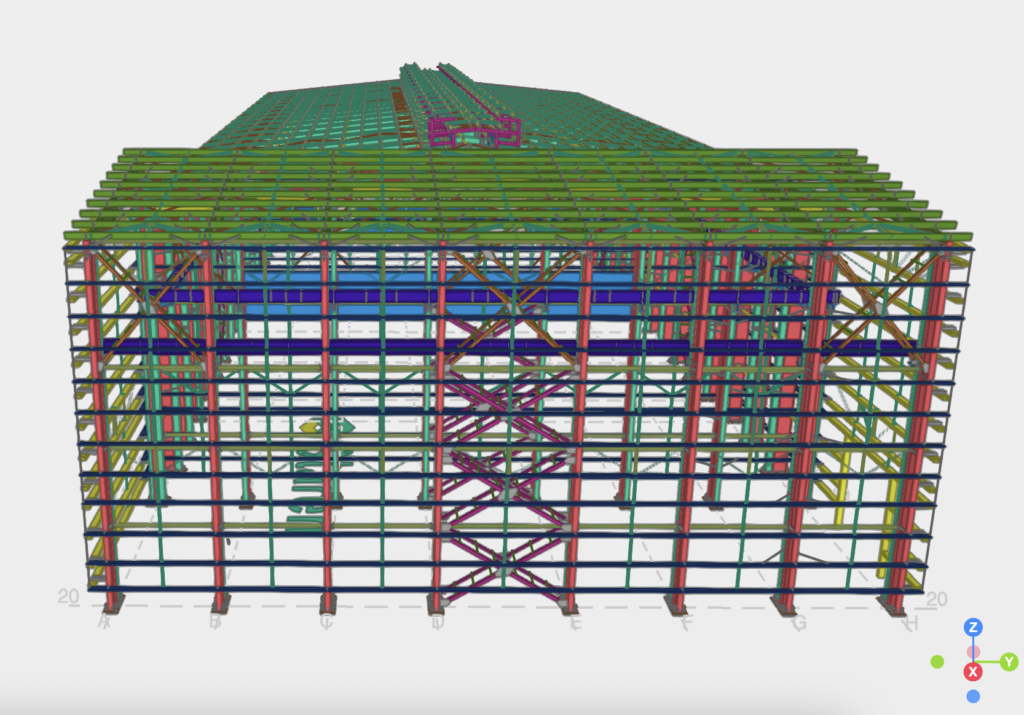

Staren Vietnam leading Steel detailer in Vietnam

Staren Vietnam is a top-tier steel detailing company delivering high-quality shop drawings and 3D models for global clients. With a skilled team and advanced tools like Tekla Structures and AutoCAD, the company ensures accuracy, efficiency, and adherence to international standards such as AISC and BS. Staren Vietnam serves diverse sectors including industrial, commercial, and infrastructure projects. Known for its reliability, timely delivery, and clear communication, the company has earned trust across the steel industry. By combining technical expertise with a commitment to excellence, Staren Vietnam continues to lead the steel detailing market in Vietnam and abroad.

Sources: Authoritative industry resources and standards documentation (AS/NZS 2312 and AS/NZS 4680) have been used to detail the requirements and recommendations for steel coatings (Implementing the AS-NZS 2312 Coating Standard Update) (specManual_08_Final_01.indd) (Advisory Note 39). These documents show how paint systems and galvanizing practices are specified for long-lasting steel protection in Australian environments.